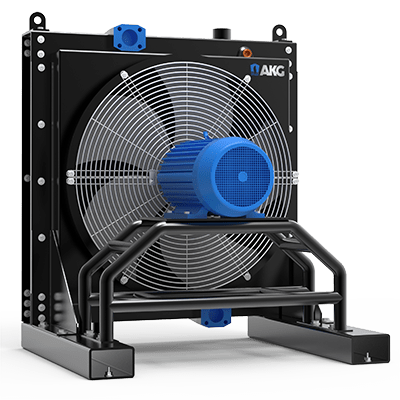

AKG Industrial Oil Coolers

Sales, Service, & Replacement

Overview:

Our high performance oil coolers provide high heat transfer rates with a minimal footprint. Most units ship from stock in 1-2 business days.

Fan Speeds:

Standard models are availalbe with rugged motors that can operate at traditional speeds, high speeds for added cooling, or lower speeds for reduced fan noise.

Motor Options:

Industrial units are available in 1 Phase, 3 Phase,

575 Volt, as well as Hydraulic Motor options. Special TECF and explosion proof motors are also avialble for customers with specific Class and Division requirements.

AKG Industrial Coolers

Oil coolers play a crucial role in ensuring your equipment's performance by regulating the quality and temperature of various oils, from small fuel coolers to large hydraulic system coolers. Whether for remote-mounted, engine-mounted, transmission-mounted, or hybrid configurations, our AKG coolers provide efficient and reliable cooling solutions tailored to a diverse range of industrial applications.

Unlike mobile coolers whose electric motors can operate on DC power, industrial units require AC power at higher voltages. Hydraulic motors are also available for some series. Various ratings are available, and almost any application can be accomodated by our diverse line of air-to-liquid coolers.

Hydraulic Systems

Hydraulic systems generate large amounts of heat during operation, which can degrade oil quality and reduce component lifespan. AKG hydraulic oil coolers regulate the temperature of hydraulic fluids, ensuring optimal viscosity and preventing system failures due to overheating. This is critical for machinery such as presses, pumps, and actuators, which rely on precise hydraulic performance to do their jobs. By maintaining stable temperatures, our coolers provide for smooth operation and prolong the life of hydraulic components.

Engine Cooling

Heat exchangers play a critical role in managing the thermal load of large engines and generators, which operate under heavy-duty conditions and generate significant heat. These systems transfer heat from engine or generator oil, coolant, or exhaust gases to the surrounding air or a secondary cooling fluid. In industrial power plants, maritime vessels, and backup power systems, these components ensure reliable operation, minimize downtime, and reduce wear on internal components, making them indispensable for high-performance, continuous-duty applications.

Power Generation

In power plants, oil coolers are essential for maintaining the temperature of transformer oil, turbine lubricants, and other critical fluids. Efficient cooling prevents overheating, ensuring safe and reliable energy production. By protecting components like bearings and gear systems, oil coolers contribute to the extended operational life and reduced maintenance of power generation equipment.

Manufacturing Systems

Automated production lines, CNC machines, and robotic systems require precise control of thermal fluid conditions to ensure smooth operation. Air-cooled heat exchangers help to manage the heat generated by lubricants and hydraulic systems, reducing downtime and wear. By maintaining stable temperatures, coolers ensure consistency in production processes and protect expensive industrial equipment from overheating.

Metal Processing

Processes like rolling, forging, and machining involve intense mechanical activity, generating significant heat in lubricants and hydraulic systems. Oil coolers dissipate this heat, preventing overheating and maintaining process stability. By protecting machinery components and ensuring the quality of finished metal products, oil coolers are indispensable in the metalworking industry.