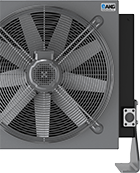

AKG Coolers for Off-Highway Equipment

These off-highway vehicles include equipment like excavators, bulldozers, loaders, and agricultural machinery. They are typically used in construction, mining, agriculture, forestry, and other industrial applications. In contrast, on-highway vehicles are primarily designed for road use, intended for commuting, personal transport, and commercial deliveries on paved roads.

Off-highway vehicles are specifically designed for use in rugged, non-urban environments where they must operate under challenging conditions. They are typically larger, more heavily constructed, and equipped with specialized components like tracks for traversing uneven terrains. These vehicles are built for durability, power, and adaptability, making them well-suited for tasks in construction, mining, agriculture, and forestry. In contrast, on-highway vehicles are designed for efficiency, speed, and comfort on paved roads. They focus more on aerodynamics, fuel efficiency, and passenger safety, making them more suited for urban commuting and long-distance travel.

One of the key differences between off-highway and on-highway vehicles lies in their hydraulic systems. Off-highway vehicles rely heavily on hydraulic systems to perform tasks like digging, lifting, and pushing. These systems control attachments such as blades, booms, and buckets, allowing the vehicle to operate efficiently under demanding conditions. However, the harsh environments off-highway vehicles faceósuch as extreme temperatures, dust, and prolonged useógenerate significant heat in the hydraulic fluids. This heat can impair system performance, making it essential to have hydraulic oil coolers. Hydraulic oil coolers are crucial for maintaining optimal hydraulic fluid temperatures, preventing overheating, and ensuring the hydraulic system operates smoothly and efficiently. They help dissipate the excess heat generated by continuous hea

Off-Highway Equipment that Use Hydraulic Oil Coolers

- Excavators: Excavators are heavy construction equipment used for digging, earthmoving, and demolition tasks. They are equipped with a boom, arm, bucket, and rotating cab, allowing them to excavate and move large quantities of soil and materials. Hydraulic systems are used to control the movement of the arm, bucket, and tracks, making hydraulic oil coolers crucial for managing the heat generated during operation.

- Loader Backhoes: Loader backhoes combine the functions of a front-end loader and a backhoe, making them versatile machines for digging, loading, and lifting materials. The front loader arm is hydraulically powered for efficient material handling, while the backhoe uses hydraulics for digging and trenching. The hydraulic oil cooler keeps the hydraulic fluid from overheating during these operations.

- Skid Steer Loaders: Skid steer loaders are compact, versatile machines used for a variety of tasks, including excavation, grading, demolition, and material handling. They move by "skidding" their wheels from side to side rather than using traditional steering. The hydraulic system is crucial for controlling the loader's arms and attachments, necessitating a hydraulic oil cooler to manage the heat generated by continuous operation.

- Trenchers: Trenchers are used to dig trenches for laying pipes, cables, and other utilities. They can be wheeled or track-mounted and are equipped with a digging chain or a blade to cut through soil. The hydraulic systems control the chain's movement and the trenching depth, requiring a hydraulic oil cooler to maintain efficient and reliable operation.