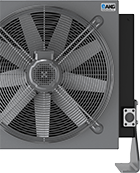

AKG Cool-Line Compressor Oil Coolers

What prompts the need for a superior air compressor oil cooling system? The conventional mechanical thermostats offer only minimal assistance. To safeguard the element, even if it means forfeiting efficiency, they often establish a high oil temperature. Consequently, compressors equipped with a mechanical thermostat tend to consume more energy than they should with a well-regulated oil temperature.

When the oil overheats, the compressor's effectiveness dwindles while energy goes to waste.

When the oil is overly cold, it makes the compressor vulnerable to condensation.

Indeed, moisture adversely affects a compressed air system's dependability.

To ensure optimal performance and longevity of your compressor, it is crucial to cool the hot oil. Here are eight reasons why cooling the oil in your compressor is imperative:

- Enhanced Lubrication: Cooling the oil helps maintain its viscosity, ensuring effective lubrication throughout the compressor system.

- Reduced Wear and Tear: Heat can degrade the oil's properties, leading to increased friction and wear on critical components. Cool oil helps minimize this wear and extends the lifespan of the compressor.

- Prevention of Oil Breakdown: Excessive heat can cause oil to break down, leading to the formation of harmful byproducts and acidic substances. Cooling the oil helps prevent this breakdown, preserving the oil's quality.

- Prevention of Oxidation: High temperatures can accelerate the oxidation process of oil, leading to the formation of sludge and deposits. Cooling the oil helps inhibit oxidation and keeps the system clean.

- Consistent Performance: Cool oil ensures consistent operation of the compressor, providing reliable and predictable performance over time.

- Reduced Maintenance Requirements: Proper oil cooling helps minimize the need for frequent maintenance and repairs, saving time and resources in the long run.