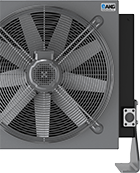

AKG Lube Oil Cooling

Air-cooled lube oil coolers play a vital role in various industries, providing efficient cooling for lubricating oil systems. These heat exchangers are designed to dissipate heat from the lubricating oil, ensuring optimal performance and longevity of machinery and equipment. In this section, we will explore the different types, materials, and applications of air-cooled lube oil coolers.

Air-cooled lube oil coolers play a vital role in various industries, providing efficient cooling for lubricating oil systems. These heat exchangers are designed to remove heat from the lubricating oil, ensuring optimal performance and longevity of machinery and equipment. AKG's lineup of rugged lube oil coolers mainly consists of brazed aluminum plate-fin cores which outperform older technologies, and deliver the most heat rejection possible per cubic inch of cooler.

Brazed aluminum air to oil coolers are widely used in various industries due to their excellent heat transfer capabilities and corrosion resistance. These coolers consist of a series of aluminum plates brazed together with intricate internal passages for efficient heat dissipation. The unique design of brazed aluminum coolers allows for compact size, lightweight construction, and high thermal efficiency. They are commonly employed in automotive applications, such as engine oil cooling, transmission cooling, and power steering systems. Additionally, brazed aluminum air to oil coolers find applications in industrial machinery, hydraulic systems, and power generation equipment. With their superior performance and durability, these coolers ensure optimal temperature regulation and enhance the overall efficiency and reliability of the equipment they serve.